Mrk Laser stands as a significant player in the field of laser technology, offering advanced solutions for industrial applications. The company's pioneering techniques and innovative products cater to diverse sectors, enhancing precision and efficiency. This article delves into the workings of Mrk Laser, exploring its product range and the technological advancements it brings to the industry.

Mrk Laser has emerged as a leader in laser technology, specializing in cutting-edge solutions that cater to various industrial needs. Known for its commitment to precision and innovation, Mrk Laser's products are designed to optimize performance across multiple sectors, including manufacturing, automotive, and electronics. This article provides an in-depth look at Mrk Laser's offerings and their impact on modern industry. Through a comprehensive examination of their advanced technology, product range, and the benefits they provide, we will explore how Mrk Laser is revolutionizing the way industries approach material processing and product manufacturing.

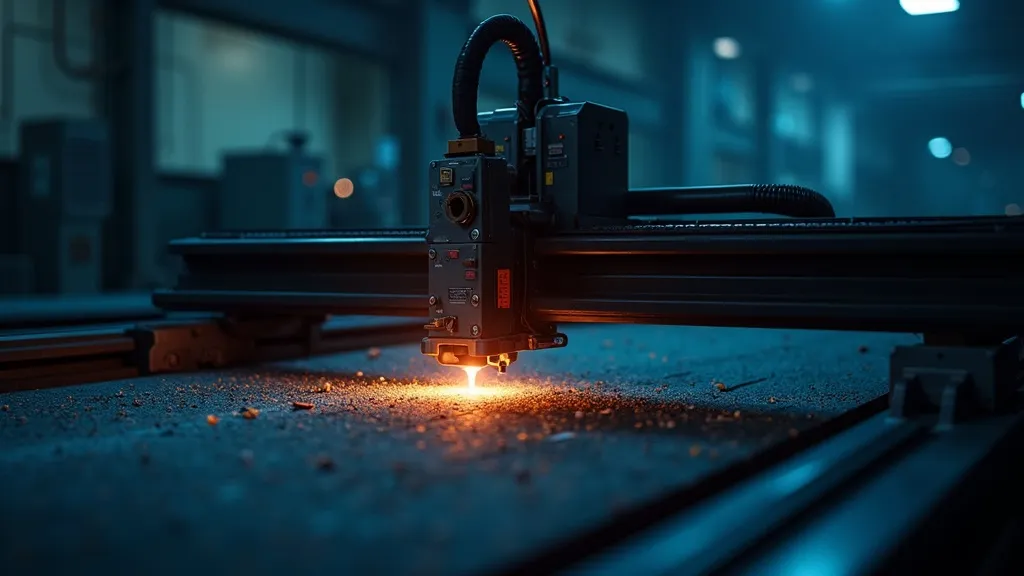

At the heart of Mrk Laser's success is its sophisticated technology. The company utilizes state-of-the-art laser systems that deliver unparalleled accuracy and efficiency in material processing. These systems are equipped with advanced features such as adaptive optics and beam shaping, allowing for precise control over the laser's focus and intensity. This level of precision not only enhances product quality but also minimizes waste, making Mrk Laser a sustainable choice for businesses aiming to reduce their environmental footprint.

Moreover, the software that accompanies Mrk Laser's systems is designed to integrate seamlessly with existing manufacturing processes. By employing advanced algorithms and machine learning, the software can optimize cutting paths and engraving techniques in real time, adapting to variations in material properties. This adaptability is crucial in industries where precision is paramount, such as aerospace and medical device manufacturing, where even the slightest error can lead to significant consequences.

Mrk Laser offers a comprehensive range of products tailored to meet the diverse needs of different industries. Their portfolio includes laser cutting machines, engraving systems, and marking solutions. Each product is designed with specific applications in mind, whether it's cutting intricate patterns in metal sheets, engraving detailed designs on glass, or marking components for traceability in the automotive industry. The versatility of Mrk Laser's products allows them to serve a wide array of sectors, ensuring that businesses have access to the right tools for their specific challenges.

Mrk Laser's cutting machines are renowned for their speed and precision. They are capable of handling a wide variety of materials, including metals, plastics, and composites. The integration of intelligent software allows for quick adjustments and real-time monitoring, ensuring optimal performance at all times. For instance, in the automotive industry, where parts must be manufactured with exact specifications, Mrk Laser’s cutting machines can produce components that fit together perfectly, reducing the need for rework and enhancing overall productivity.

Additionally, these machines feature high-speed motion control systems that increase cutting speeds without sacrificing quality. This is particularly advantageous in high-volume production environments where time is of the essence. The ability to execute complex cuts with fine details further positions Mrk Laser as a preferred choice for businesses looking to innovate their product offerings.

The company's engraving systems are ideal for creating detailed designs on various surfaces, while their marking solutions provide good, high-contrast marks for identification and traceability purposes. These systems are particularly popular in the electronics industry, where component identification is critical. For example, in the production of consumer electronics, clear and durable markings are essential for both compliance and brand identity. Mrk Laser’s marking solutions ensure that every component is easily identifiable, which streamlines assembly processes and reduces the potential for errors.

Furthermore, Mrk Laser's engraving technology allows for personalization options that are increasingly in demand across various sectors. Custom engraving can add significant value to products, making them more appealing to consumers. This capability is particularly beneficial in the gift and promotional products industry, where unique designs can enhance customer satisfaction and brand loyalty.

Choosing Mrk Laser brings numerous benefits to businesses. Firstly, the precision and speed of their systems lead to increased productivity, reducing production times and costs. Secondly, the flexibility of their machines allows for customization, catering to specific project requirements. This is especially important in industries where customer specifications may vary widely. Lastly, the durability and reliability of Mrk Laser's products ensure good performance, providing a solid return on investment for companies.

Moreover, Mrk Laser actively engages with its customers to understand their unique challenges and requirements. This collaborative approach enables the company to offer tailored solutions that address specific pain points, facilitating smoother integration of their technology into existing workflows. As a result, businesses can achieve greater operational efficiency and improved product quality, ultimately leading to enhanced competitiveness in their respective markets.

| Condition | Requirement |

|---|---|

| Installation Space | Adequate space for equipment and safety measures. |

| Power Supply | Stable and sufficient power supply to operate the laser systems. |

| Training | Operators must undergo training to ensure safe and efficient use. |

| Maintenance | Regular maintenance schedules to ensure optimal machine performance. |

In addition to these basic requirements, businesses must also consider the integration of Mrk Laser systems into their existing production lines. This may involve customizing workflows and ensuring that other machinery can effectively communicate with the laser systems. Companies may benefit from consulting with Mrk Laser’s experts during the planning phase to identify potential challenges and develop strategies for seamless implementation.

To further illustrate the impact of Mrk Laser's technology, we can explore several case studies that highlight its effectiveness in real-world applications.

One of Mrk Laser's notable implementations occurred in an automotive manufacturing plant where precise cutting and engraving were crucial for vehicle components. The facility was facing challenges with the accuracy of traditional machining methods, resulting in increased waste and production delays. After integrating Mrk Laser's cutting machines, the plant reported a 30% reduction in material waste and a significant boost in production speed. The high precision of the laser systems allowed for tighter tolerances, ensuring that parts fit together seamlessly in the assembly line.

Additionally, the engraving solutions provided clear identification marks on components, which simplified inventory management and traceability. This not only enhanced operational efficiency but also improved compliance with industry regulations regarding component identification.

In the electronics sector, a leading manufacturer of consumer electronics turned to Mrk Laser to enhance their product identification processes. The company needed a reliable method for marking thousands of components quickly and clearly to facilitate assembly and quality control. Implementing Mrk Laser’s marking solutions allowed the manufacturer to achieve high-contrast marks that were not only durable but also resistant to wear and environmental factors.

The results were impressive: the manufacturer reported a 40% increase in production efficiency, as the laser marking system reduced the time required for component identification and inspection. Moreover, the flexibility of the system enabled quick changes to marking designs, allowing the company to easily adapt to new product lines and branding requirements.

In the aerospace industry, where safety and precision are paramount, a major aerospace manufacturer integrated Mrk Laser’s cutting and engraving systems to produce intricate components for aircraft engines. The stringent requirements for weight and material strength necessitated the use of advanced manufacturing techniques. Mrk Laser's technology enabled the manufacturer to achieve the necessary precision while using lightweight materials, significantly enhancing performance and fuel efficiency.

The implementation of Mrk Laser systems not only improved the quality of the components but also reduced production time by 25%. This advancement allowed the manufacturer to meet tight delivery schedules and enhance its competitive edge in the market.

As technology continues to evolve, Mrk Laser is well-positioned to lead the charge in laser innovation. The company is actively researching and developing new laser technologies that promise to enhance capabilities further and address the challenges faced by modern industries. Trends such as automation, Industry 4.0, and the increasing demand for customization are driving the evolution of laser technology.

One of the significant trends is the rise of automation in manufacturing processes. Mrk Laser is exploring the integration of artificial intelligence and machine learning with its systems to create fully automated solutions that can operate with minimal human intervention. This shift not only increases efficiency but also allows for greater precision and consistency across production lines.

Another trend is the growing demand for customization in products. Consumers are increasingly seeking personalized items, prompting manufacturers to adapt their processes to accommodate unique specifications. Mrk Laser’s systems are inherently flexible, making them ideal for businesses looking to offer tailored solutions without sacrificing quality or speed.

In conclusion, Mrk Laser exemplifies innovation and reliability in laser technology, offering solutions that drive industrial excellence. By understanding the capabilities and applications of Mrk Laser's products, businesses can make informed decisions that enhance their operational efficiency and product quality. As industries continue to evolve, Mrk Laser remains poised to lead the charge in technological advancement, setting new standards in precision and performance. The company's ongoing commitment to research and development ensures that it will continue to meet the changing needs of its customers, ultimately shaping the future of manufacturing and material processing.

With its comprehensive product offerings and dedication to sustainability, Mrk Laser stands as a testament to the transformative power of laser technology in the industrial landscape. Whether it’s through improved efficiency, enhanced product quality, or the ability to adapt to new challenges, Mrk Laser is an invaluable partner for businesses looking to thrive in an ever-competitive market.

Explore the Tranquil Bliss of Idyllic Rural Retreats

Ultimate Countdown: The 20 Very Legendary Gaming Consoles Ever!

Understanding Halpin and its Influence

Affordable Full Mouth Dental Implants Near You

Discovering Springdale Estates

Illinois Dentatrust: Comprehensive Overview

Embark on Effortless Adventures: Unveiling the Top in Adventures Made Easy Outdoor Equipment

Unveiling Ossur Valves: Innovation in Prosthetics

Unlock the Full Potential of Your RAM 1500: Master the Art of Efficient Towing!